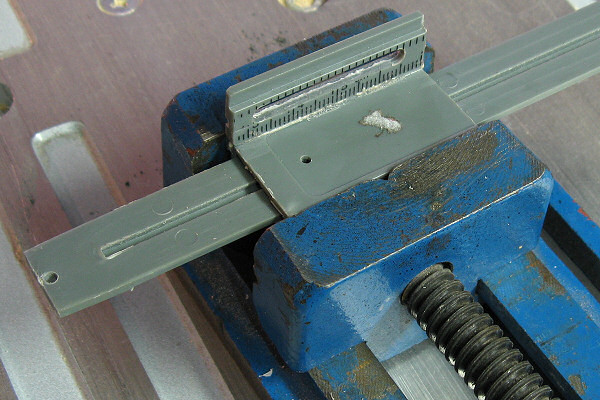

The mini-lathe was not equipped with a scale measuring the spindle depth. Probably the cheapest solution is a PVC caliper for 0,5 Eur.

experimentálny web ;-)

The mini-lathe was not equipped with a scale measuring the spindle depth. Probably the cheapest solution is a PVC caliper for 0,5 Eur.