Bench vise in my workshop needs some reparation after several years of use:

Instead of simple replacement of the steel plate I decided for change the construction. For the force transmission between the spindle and jaw the roller bearings will be used. It is necessary to make washers for the axial ball bearing.

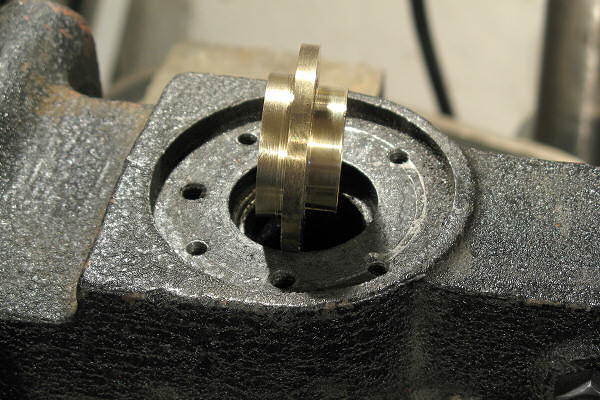

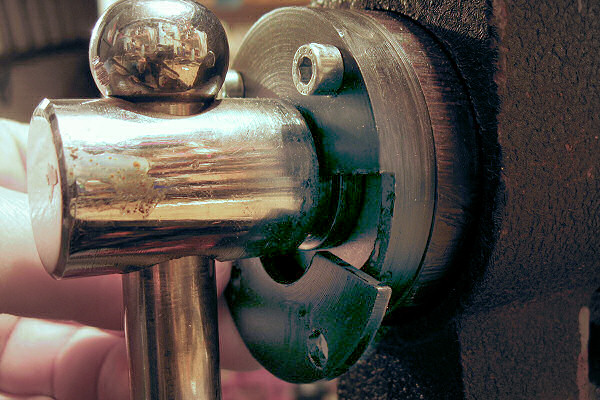

Between the jaw and bearing I made a brass washer.

This piece fits to the mortice in the jaw, enlarges interface, holds bearing, centers position of the spindle and defines bearings clearance.

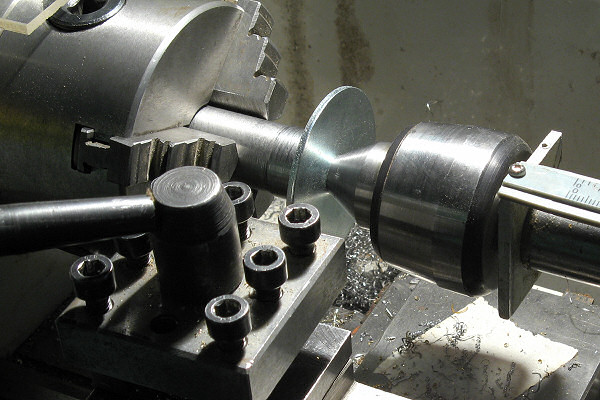

Between the mortice on the spindle and the bearing the iron spacer was turned. It was turned from the washer for wood construction (ISO 7094).

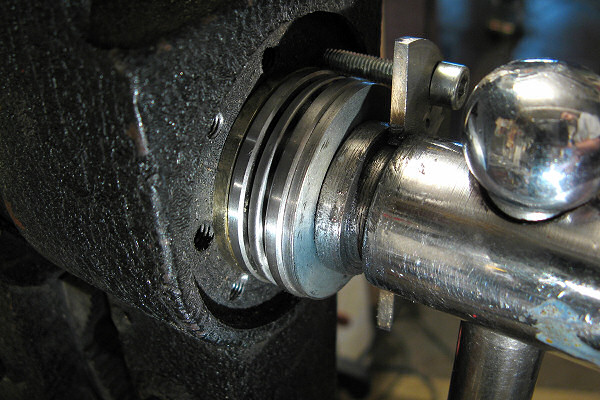

The axial bearing with the washers works fine when closing the vise. The goup of bearing and washers will be covered by the lid, which will fit into the slot on the spindle. The Lid will be fastened using screws and tranfers power from the spindle while the vise opening.

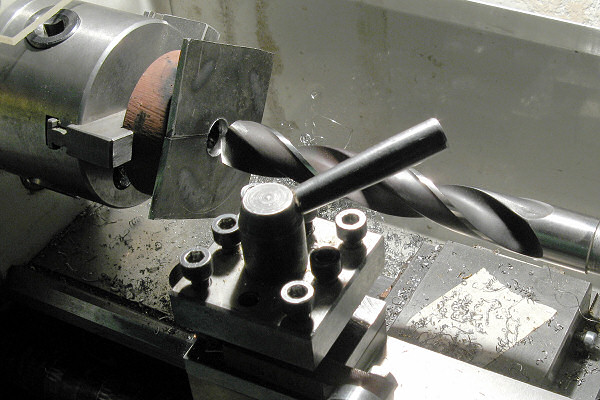

The lid is made from the pipe and piece of sheet. The pipe is sqared using lathe.

The sheet is cutted on two parts and welded tothe pipe.

Hole, which fits to the spindle is drilled into the lid and sheet turned down to the pipe diameter.

One half of the sheet remains on the lid. Second half is removable due to assembling/dissassembling.

Four screws keeps the lid and produces the minimum force under which the axial bearing works.

Length of maximum opening of jaws was reduced for 20 mm, but the 150 mm is still enaugh.